BSL unit AZIS-1200 consists of the following subassemblies:

- Turning station with hydraulic and mechanical chain tightening.

- Horizontal pan line (lying)

- Dynamic winning crusher

- Rising pan line

- Supporting structure of conveyor driving set

- Driving set of BSL unit

- Combined turning station of belt conveyor with transfer point

- “BISUP-W” device

- “SUPEN W/F” device

- Typical scraper conveyor couplings, cable baskets

- Electrical equipment

- Hydraulic componentry

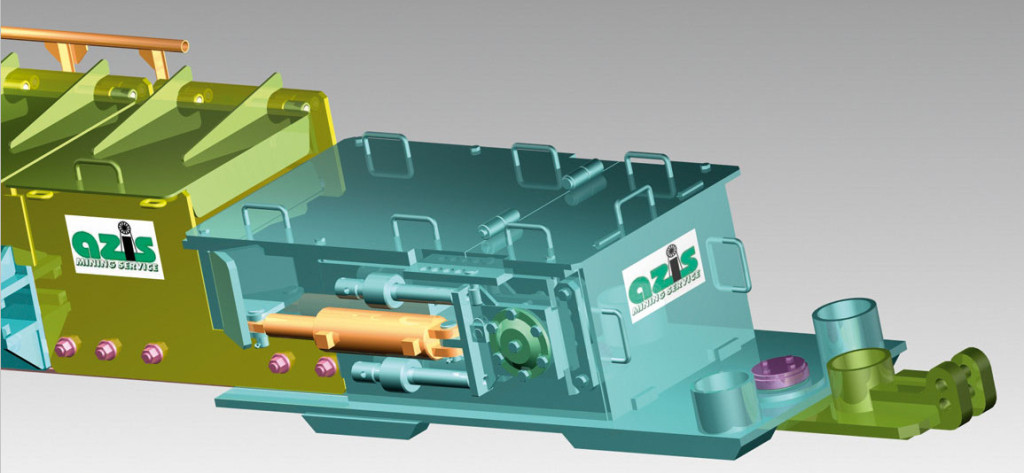

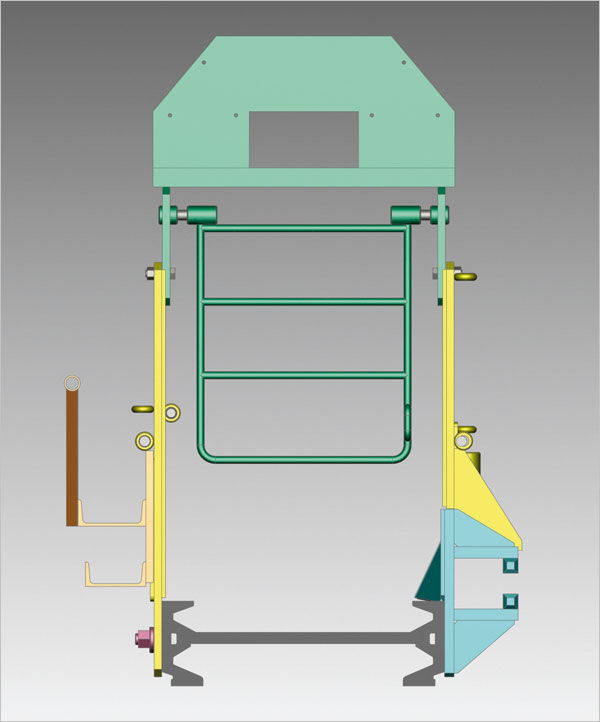

Turning station

Turning station

Turning station

The turning station is made of high strength metal plates as a rigid and welded box construction. It is equipped with a toothless return drum with self-aligning bearings on both sides. It is also equipped with a hydraulic and mechanical chain tightening system. The chain is hydraulically tightened by actuators powered by the hydraulic system of the powered roof supports. The chain is mechanically tightened by bolts, which enable precise regulation of scraper chain tension, preliminarily tightened by the hydraulic system, and securing the setting. The turning station is equipped with two anchor slots used to anchor the BSL unit in the gate road by means of anchor props. In gate roads with inclination from ±12o to ±18o where AZIS-1200 is mounted, the turning station is additionally equipped with an extra anchor slot connected with pivot bolts, which enables attaching an extra anchor prop and the “BISUP-W” device.

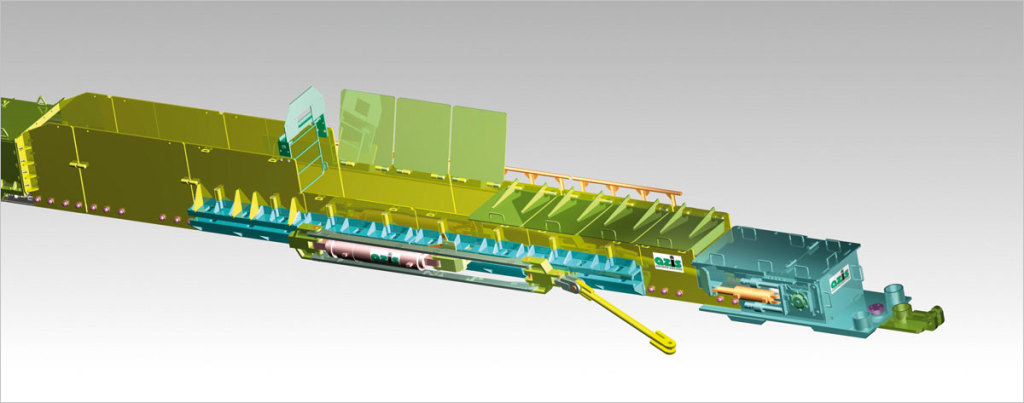

Horizontal pan line

Horizontal pan line with mounted “SUPEN W/F” device and spill plates

Horizontal pan line with mounted “SUPEN W/F” device and spill plates

<pThe horizontal pan line is built from line pans to which spill plates are mounted. Spill plates are mounted in such a way as to form a rigid, self-supporting structure with pans. Spill plates in the operation section of discharge drive of AFC (length according to customer’s requirements), on the side of coal sidewall are always constructed as divided and easy to disassemble for the duration of AFC rebuilding. Depending on the version, the conveyor can be equipped with divided spill plates, adapted to work with the “SUPEN W/F” device. On the opposite side of the conveyor in the section of longwall coal transfer point the following spill plates can be mounted, depending on the customer’s requirements:

- uniform, high and straight with cover plates of the pan line, securing the route of the conveyor after the rebuilding of the longwall discharge,

- uniform and buckled – the route is secured by a winding cover plate,

- divided – the route is also secured by a winding cover plate,

- revolving – securing the route of the scraper conveyor after the rebuilding of the discharge drive of AFC, adapted to work with spill plates of “SUPEN W/F” device as well as divided spill plates; their advantage is a low height of the route from the discharge to turning station after securing it, which enables material transport at the entrance to the face and safe passage of staff through the route of the conveyor.

|  |

| Revolving spill plates adapted to work with divided spill plates | Revolving spill plates adapted to work with spill plates of “SUPEN W/F” device |

A pre-crusher pan line can consist of uniform, high and straight or buckled spill plates, on which a safety gate and cable baskets are mounted.

Buckled spill plates that are mounted on the pre-crusher pan line increase the pan line cross-section, thus eliminating the jamming of large coal lumps which pile up directly before the crusher, and increasing the flow of winning haulage by the conveyor.

Spill plates mounted on the pre-crusher pan line can be equipped with suitable fastenings to attach special rods connecting the pan line with the crusher, which transfer a load during “AZIS-1200” advance, and to some extent lightening the self-supporting structure of the whole horizontal pan line.

|  |

| Pre-crusher pan line with straight spill plates mounted | Pre-crusher pan line with buckled spill plates mounted |

The height of spill plates is suited to customer’s needs. Their solid construction prevents their deformation during operation.

Dynamic winning crusher

The BSL unit can work with the following types of crushers: SB-900; KRUK-1000P; KRUK-1000P; KRUK II; UKU-1500; WB-1300; DLB-1000K; DLB-800; KKWB-1; DU-2P6; SB-63; KKBW-1 or with other technically approved and certified construction to be operated in underground workings.

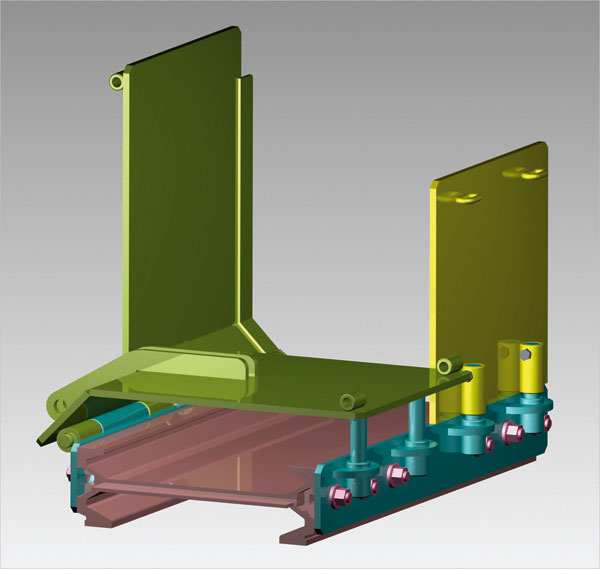

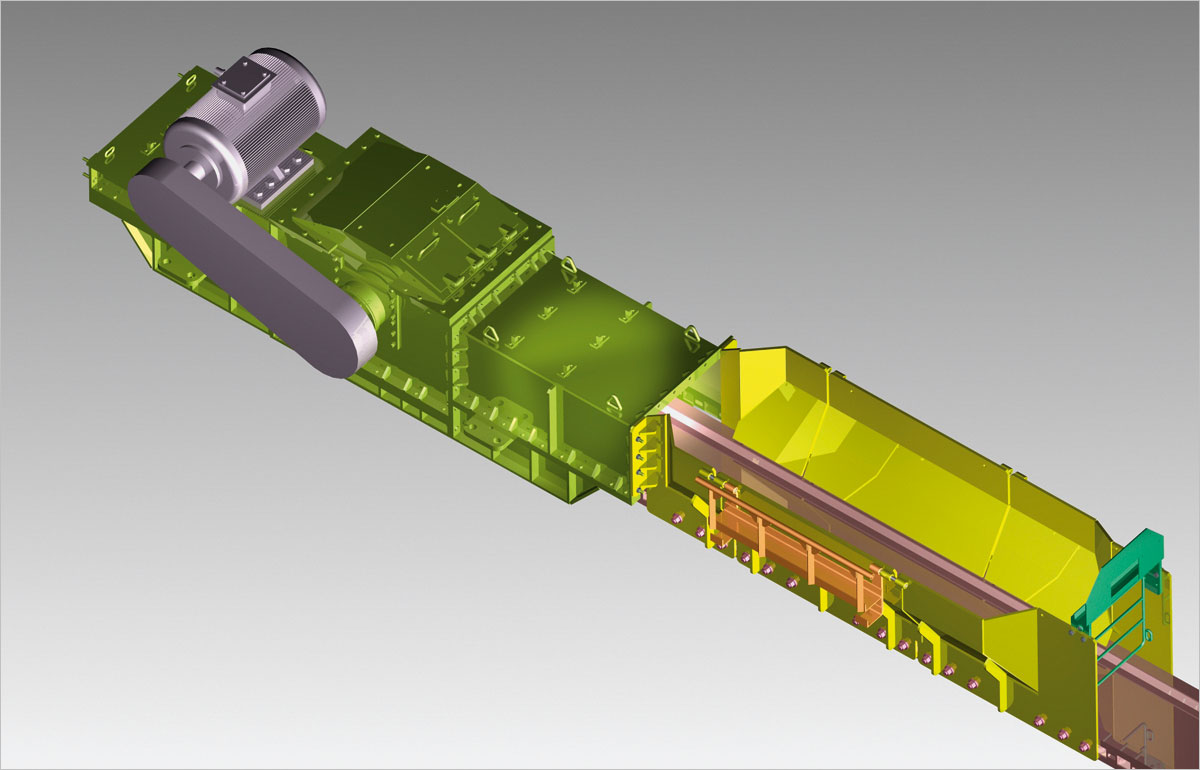

Rising pan line

The rising pan line is built of straight pans, a concave pan, and depending on the type of drive frame used an attachable or arched pan. Spill plates are mounted on pans to make a self-supporting structure. The height of spill plates is suited to individual customer’s requirements. The rising part of the pan line is placed on a special supporting structure, and has bottom plates screwed underneath which close it from the bottom and make it rigid, and also shield the bottom part of scraper chains. The rising pan line is equipped with cable baskets and cable bushes leading a trip cord. In its bottom part there is a passage for staff. In the part lying on the floor special platforms are mounted, designed for mounting electrical devices, tool boxes etc., which advance together with the BSL unit. The drive frame is equipped with tops and also mounted on the supporting structure.

Supporting structure

The supporting structure depending on customer’s requirements can be of constant height and drive frame inclination angle adjusted to a specific conveyor height, with manual regulation of the height and inclination angle and with hydraulic regulation of the height and inclination angle with an optional rotation of the drive frame in relation to the longitudinal axis of the belt conveyor. Depending on the drive frame used, the conveyor driving set is seated on the supporting structure on the subdrive plate or on two subdrive beams.

The supporting structure of “AZIS-1200” is always equipped with a mounting beam of the “BISUP-W” device, a mounting beam of the self-advancing transfer point of the belt conveyor and screws to its regulation in the axis of the scraper conveyor. The structure is connected with the crusher with pull rods, which enables pan line lightening during an advance.

Where the BSL unit works in workings with inclinations from ±12o to ±18o, the supporting structure is equipped with anchor slots of hydraulic props, which stabilise the unit in relation to the working.

Driving set of BSL unit

The driving set of BSL unit is matched to the scraper conveyor every time, due to customer’s requirements. The driving set of “AZIS-1200” is every time made up of by devices technically approved and certified to be operated in underground workings.

Due to the symmetrical construction of drive frames used it is also possible to use systems with a single drive mounted on the left or right side of the conveyor. Where the customer changes the type of the reduction gearbox, we provide special distance elements mounted on the drive frame, which enable its change without the necessity of changing the frame type.

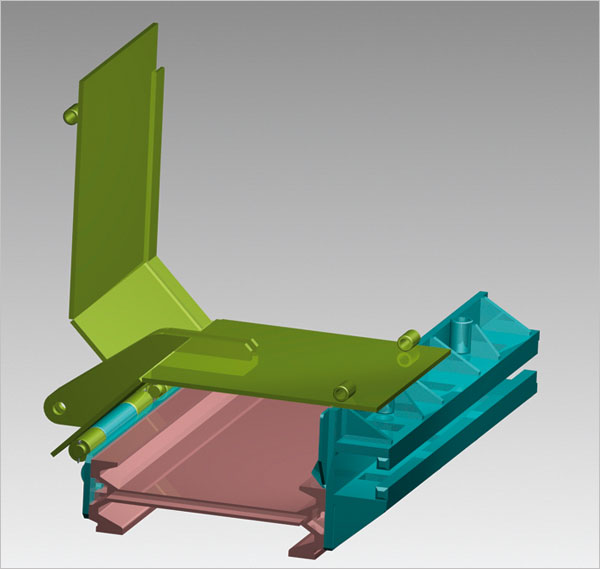

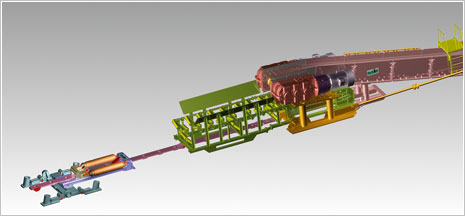

Combined turning station of a belt conveyor with transfer point

The combined turning station of a belt conveyor with a transfer point is made up of the belt conveyor turning station connected with the structure supporting roller brackets, flightbar and chute plates. The turning station is mounted with pivot bolts on the beams of the driving set supporting structure. The turning station is deflected in relation to the route axis by the joint by means of a screw, which is seated in the supporting structure on the one side, and in a threaded hole of the supporting structure of the discharge drive on the other.

The belt conveyor turning station with a transfer point is additionally mounted on runners of the self-advancing transfer point connected to the supporting structure of the scraper conveyor discharge drive with pivot bolts.

Turning stations of belt conveyor used: GWAREK 1200M; GWAREK 1000M; MIFAMA 1200; MIFAMA 1000; PTGm 1200; PTGm 1000; PTG-50/1000; PIOMA 1200; BOGDA 1200; GWAREK B 1200S or other belt conveyors technically approved and certified.

“BISUP-W” and “SUPEN W/F” devices

These devices are the separate production of AZIS and have separate certifications.

Read more:

Our scraper conveyors are designed for high productivity, reliability and duration due to their simple and solid construction. Innovative solutions used in its advance system offer high mobility. Through our construction we always try to meet our customers’ expectations along with the observance of safety conditions.

Our conveyors are manufactured in accordance with individual customer’s requirements, and at the same time obtaining appropriate certifications for their operation.

Rising pan line with BISUP-W device mounted

Rising pan line with BISUP-W device mounted